file set up for laser plotter

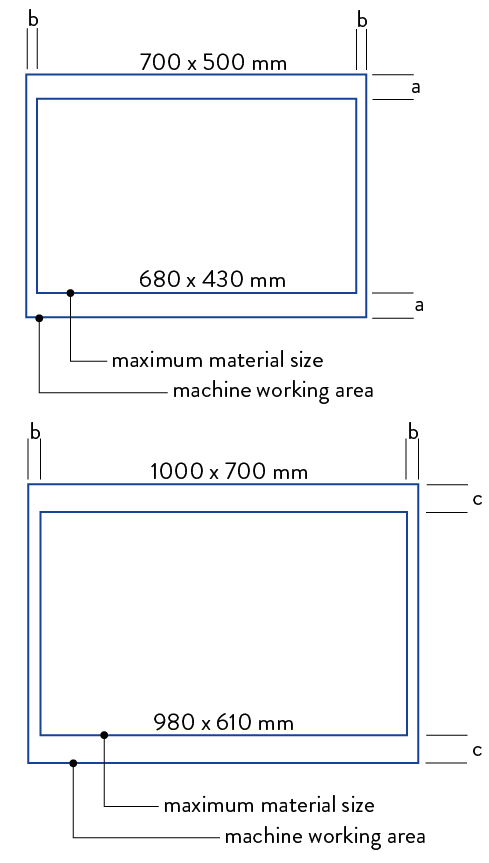

In order to draw the pieces correctly, you should proceed as if you were cutting them manually: it is necessary to draw the geometries with the real measures already reduced to the scale of the model and in millimetre units of measurement. The pieces to be cut with the plotter must be positioned inside two frames with the longer side placed horizontally and the following requirements:

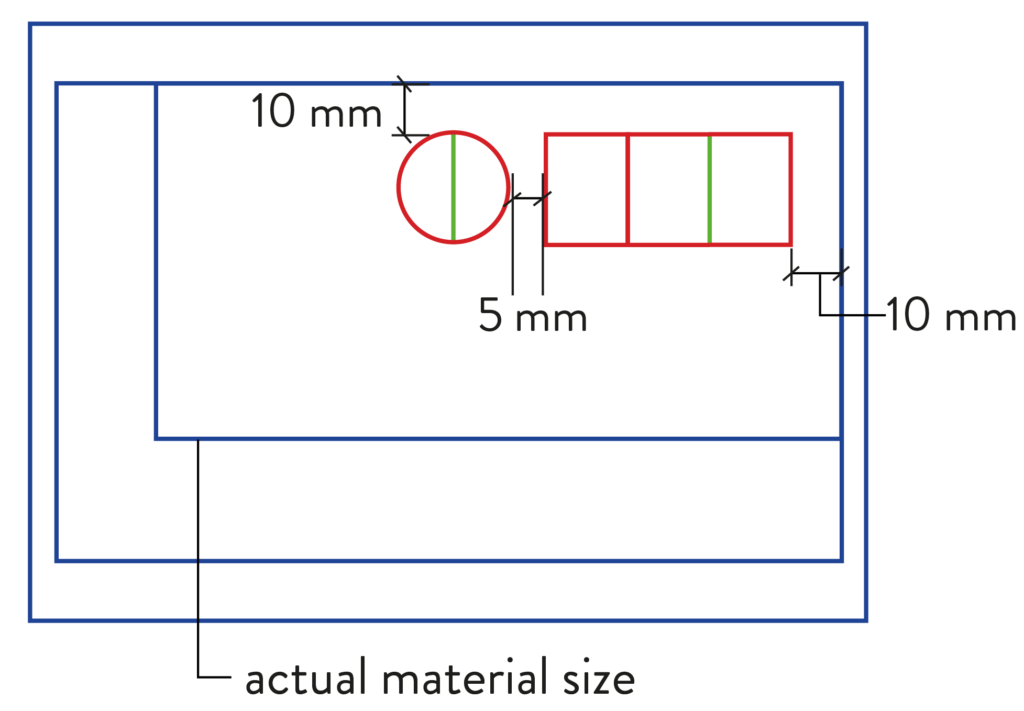

The material to be inserted in the machine must be the same size as the inner frame. If the material is smaller in size than the inner frame, you can add a third frame with the size of the material in your possession. The drawings of the pieces to be cut must be placed in the inner frame with at least 10 mm of distance from the edge, starting from the top right-hand corner.

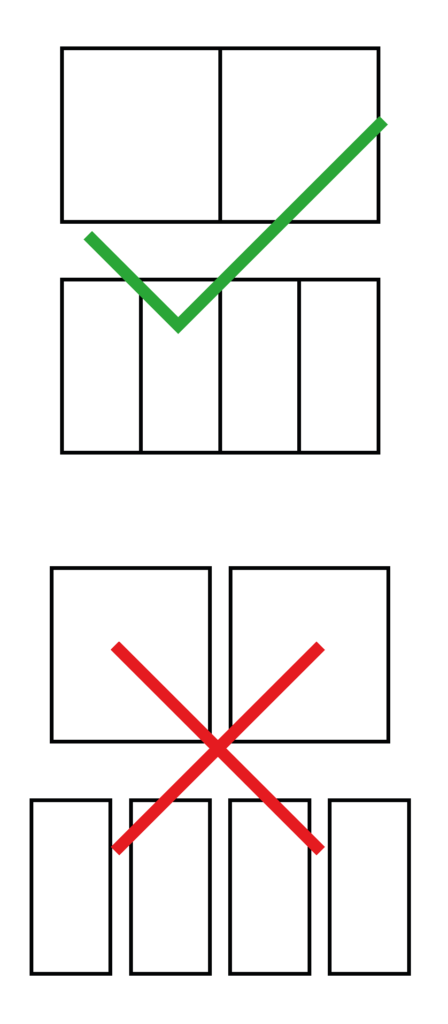

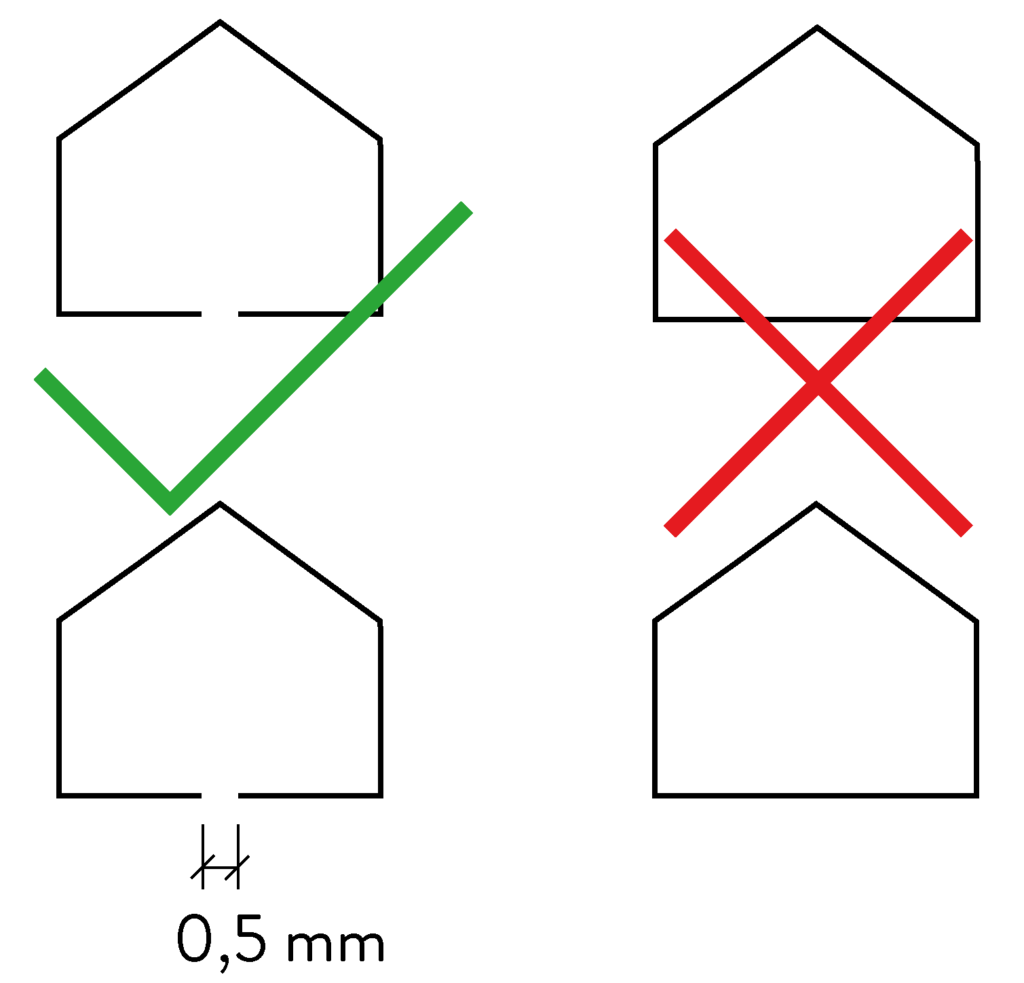

Arrange the pieces to be cut inside the frame with at least 5 mm distance from each other if they are complex or curved shapes, however if the shapes are simple and straight, as in the case of rectangles, the pieces should be joined together to reduce the cutting time.

Assign the following colours to the different drawing elements:

| blue for the frames |

| red for the elements to be cut |

| green for the elements to be engraved |

The vector file must be in .dxf 2000 format in order to be imported into the cutter management program.

To cut several sheets of material, it is necessary to prepare an equivalent number of files.

To download the template click here

useful tips

The file used for cutting must contain only the pieces to be cut, the frames and no drawings on frozen or switched off layers. There must be no overlapping lines in the drawing to avoid pronounced burns. If you draw with AutoCAD, we suggest using the _overkill command, which, inside a selection window, eliminates all possible overlapping lines keeping only the longest ones.

The machine management software does not recognise complex entities such as groups, regions or splines, so it is necessary to transform them into lines or polylines. If you draw with AutoCAD, we suggest using the _editpl command.

In order to avoid producing fragile or unusable pieces, it is necessary to check that in the drawing there are no elements to be cut or engraved with related dimensions or distances less than 0.7 mm, for example, window frames, porches, or decorative elements.

The laser works with a flow of air to extract fumes: in case of very small pieces, those risk being displaced. It is advisable not to close the cutting perimeter completely, so that the piece remains attached to the sheet and can be later separated by manual cutting.

with the laser plotter it is possible to cut

- paper and cardboard up to 360 gr/sqm;

- grey or ivory cardboard up to a thickness of 2,5 mm;

- rigid plastic, only: extruded and cast methacrylate, PMMA, Perspex, Plexiglas, up to the thickness of 5 mm.

it is not possible to cut

- plastic coated, varnished or glued cardboard;

- polycarbonate and pvc such as vinyl and forex;

- thermoplastic polymer HDPE and polystyrene;

- soft plastic such as polypropylene or acetate.