use of the hot wire

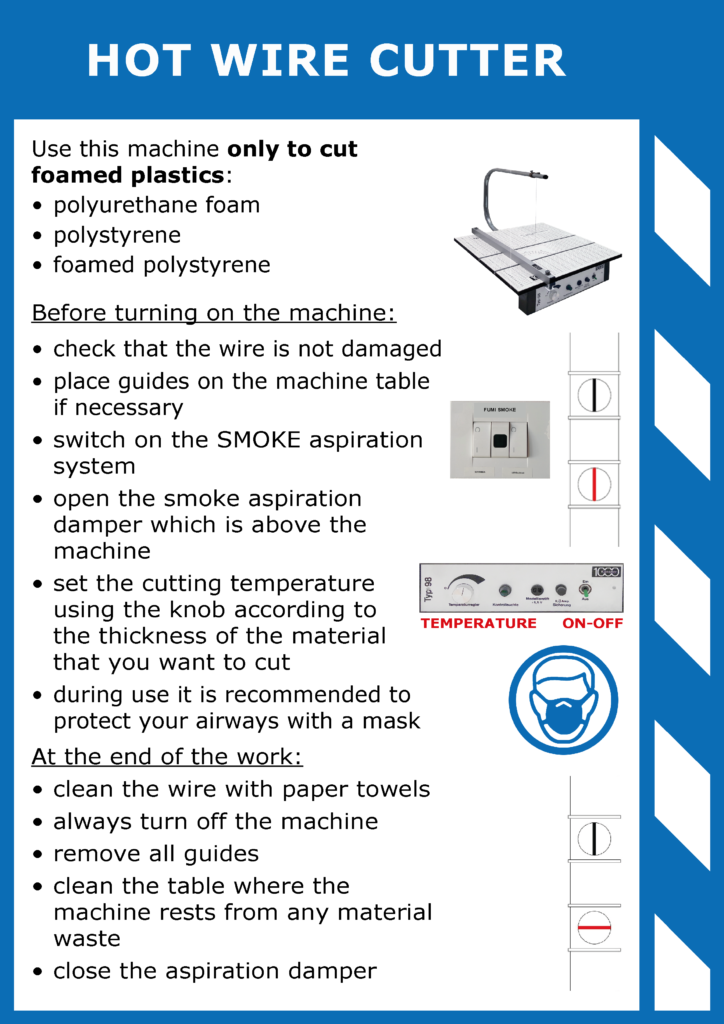

1. before turning on the hot wire

Read carefully the signage displayed in the DRILLING Lab.

Check the integrity of the wire. If necessary, modify the standard configuration of the hot wire, varying the inclination of the wire and/or fixing any guides.

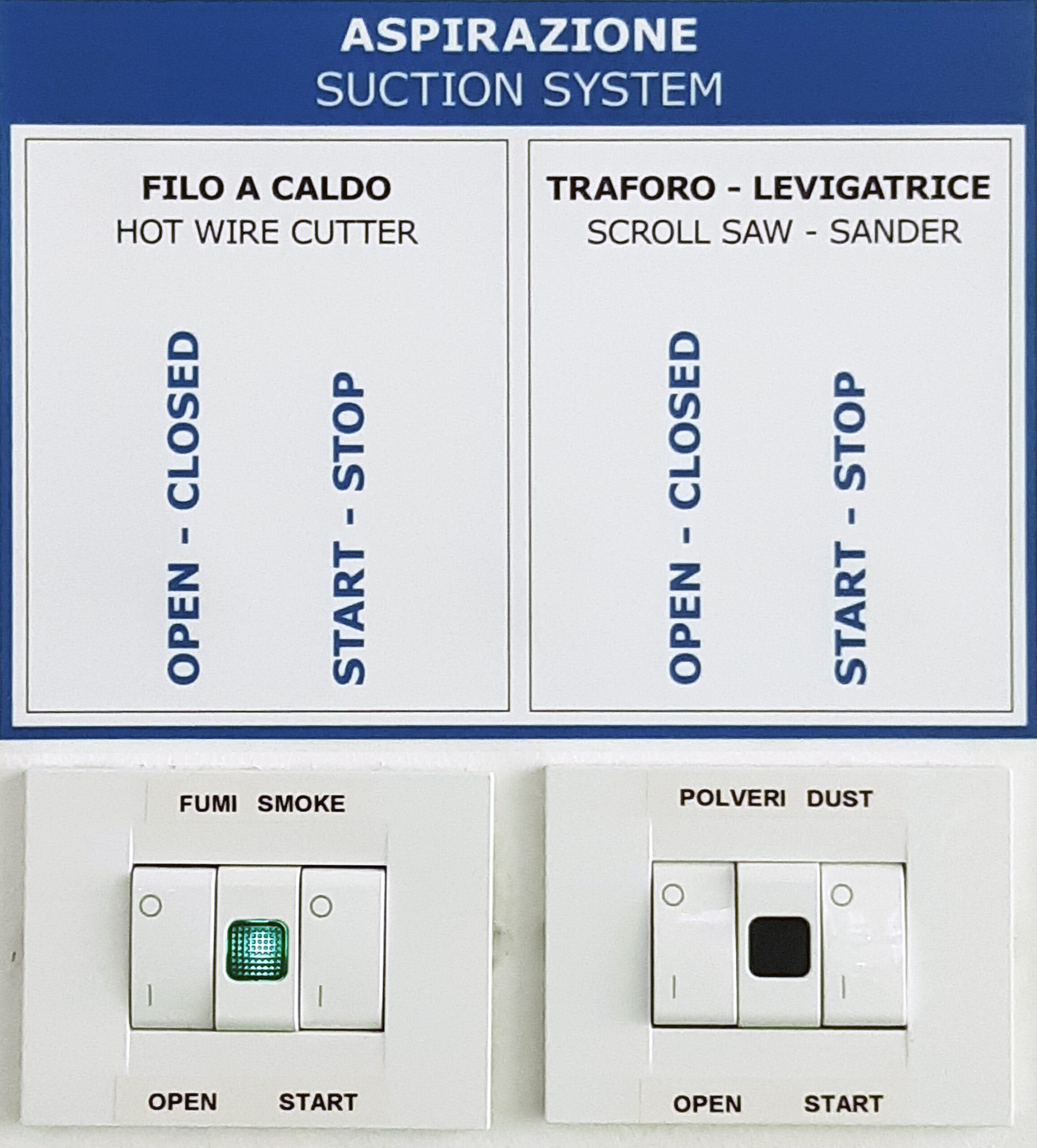

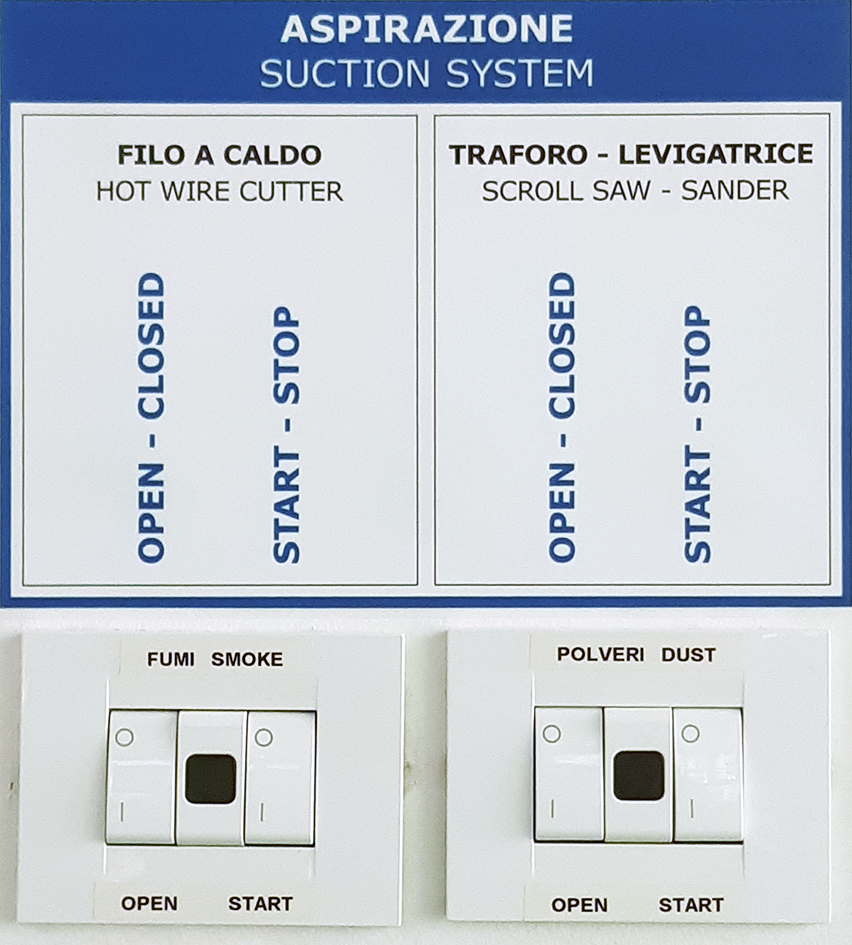

Turn on or verify that the smoke extraction system is active: switches, OPEN and START, in position I and wait for the green light to turn on.

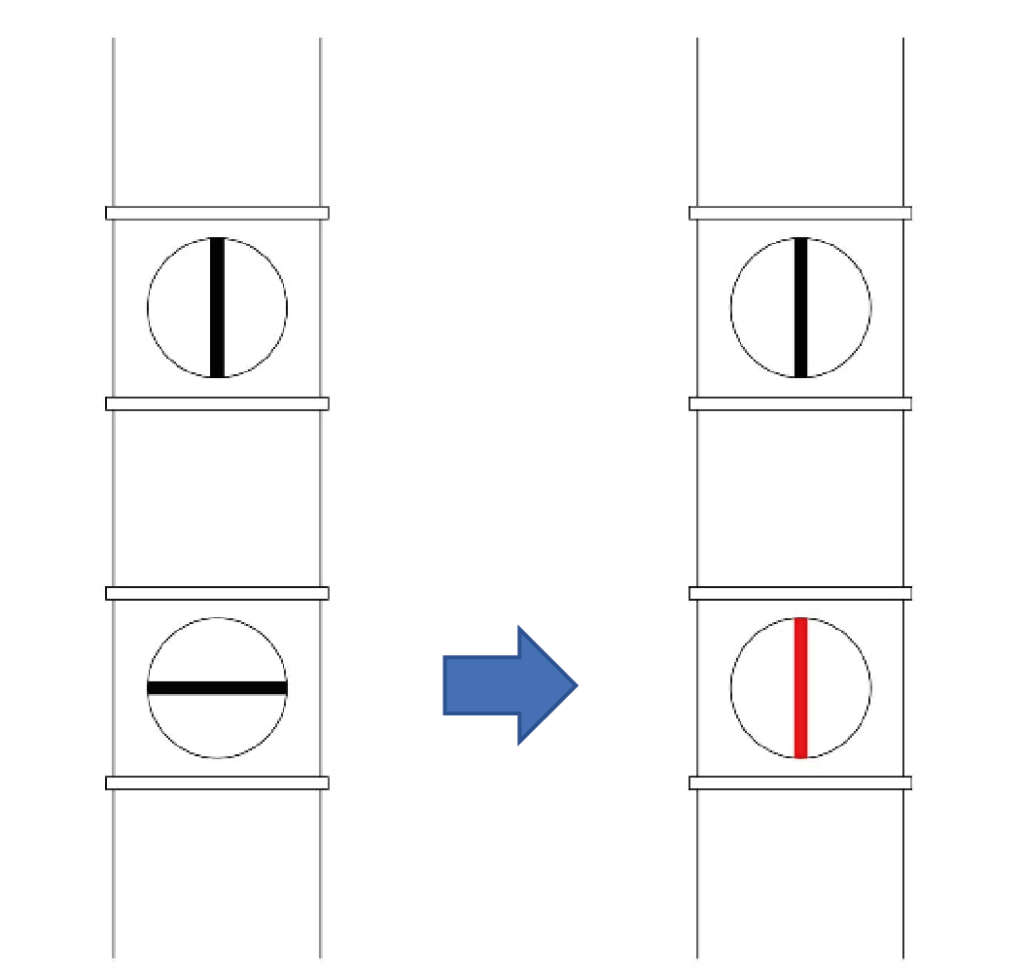

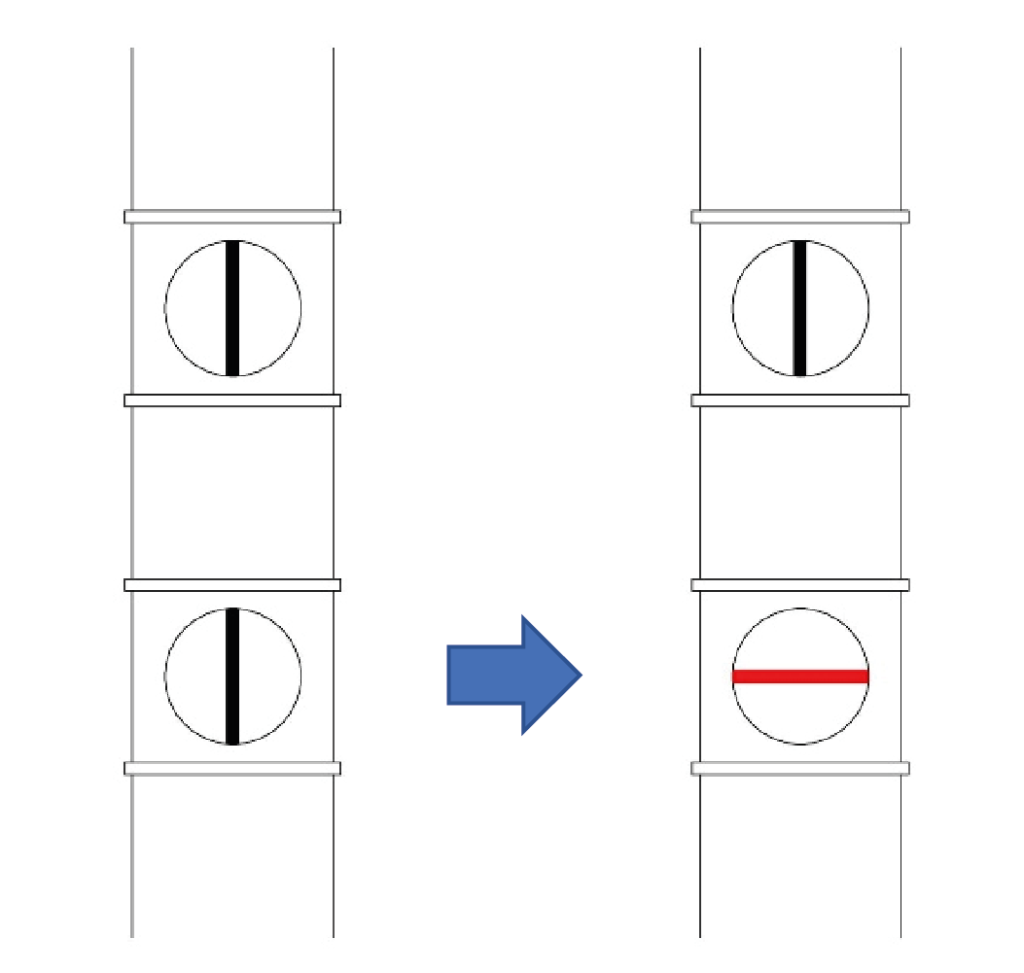

Open the lower damper, placed on the suction pipe above the hood, in correspondence of the machine that you intend to use, rotating it in vertical position.

2. turning on the hot wire

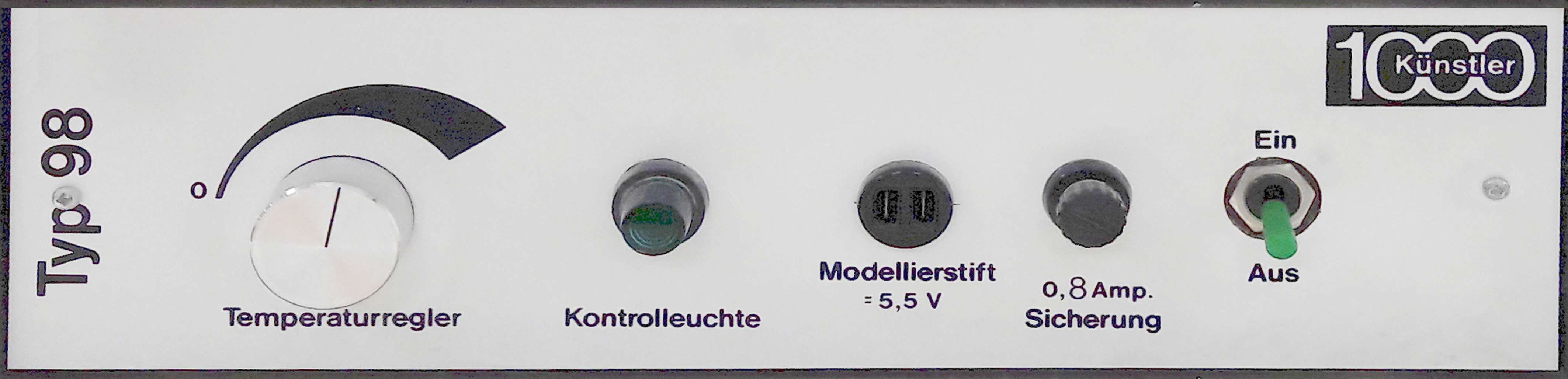

To operate the hot wire, press the ON/OFF (I/O) switch on the side of the machine and adjust the temperature according to the density of the material.

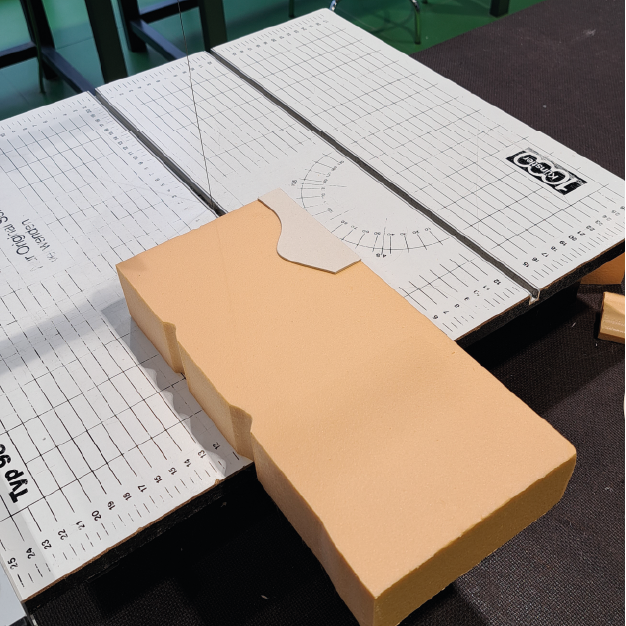

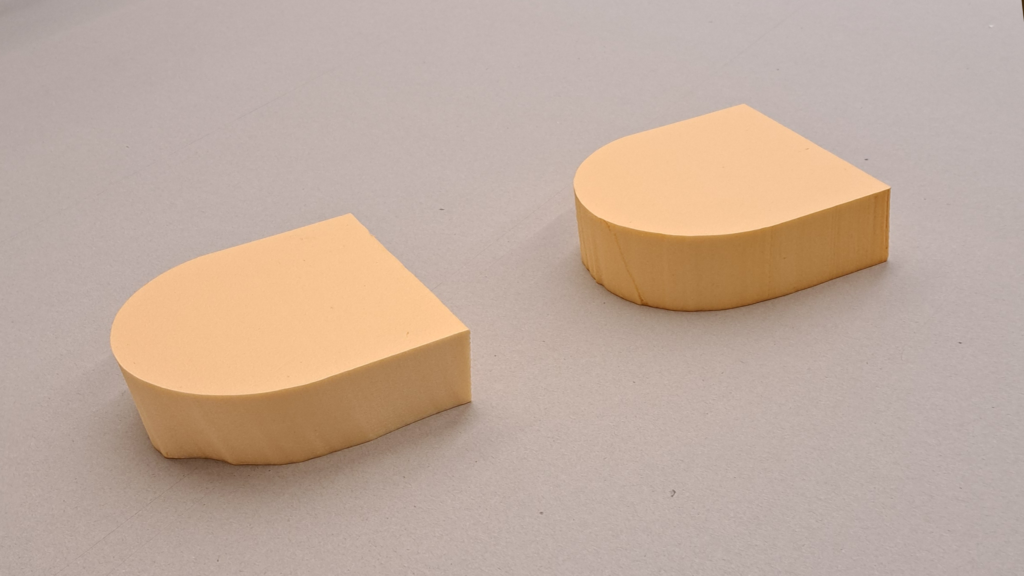

3. cutting of expanded plastics

Place the foam sheet on the work surface of the machine and move it against the wire at a speed as uniform as possible. The change of speed involves a different melting of the plate and therefore a discontinuous cutting surface.

To facilitate the maintenance of a constant speed: for cutting simple shapes, use guides while for complex shapes, make cardboard shapes to be applied on the double-sided adhesive plate.

To prevent the material residues on the wire from melting at the end of the cut, generating smoke, and compromising the quality of the next cut, clean the wire with absorbent paper while the machine is on and take care not to burn yourself.

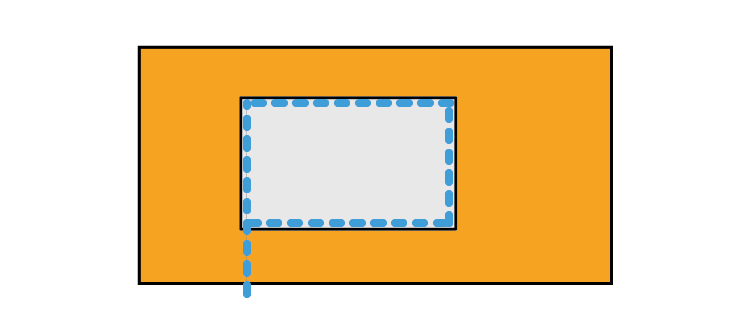

For holes inside the piece, unlike other equipment such as the scroll saw, where you can unhook the blade and insert it inside a hole to complete the cut of the inner hole, in the case of hot wire it is not possible to disassemble the wire so the hole will necessarily be connected to the outer perimeter with a cut.

4. at the end of work

HOT WIRE SHUTDOWN: Press the switch in the OFF position and never move away from the workstation leaving the machine running.

RESTORING THE STANDARD CONFIGURATION: leave the wire perpendicular to the work surface and remove any guides.

CLEANING OF THE WORKING AREA: remove the waste from the table and the surrounding working area and throw it in the appropriate bin.

SUCTION INTERRUPTION: close the lower damper, placed on the suction pipe above the hood, in correspondence of the machine that has been used, rotating it in horizontal position.

SWITCHING OFF THE EXTRACTION SYSTEM: Put the two OPEN and START switches of the dust extraction back in O position.

LEAVE THE SYSTEM ACTIVE IF OTHER HOT WIRES ARE IN OPERATION.

helpful tips

To optimally adjust the temperature and allow the advancement of the sheet at a uniform speed carry out a cutting test.

If you set an inadequate temperature that leads to applying too strong pressure against the wire, this will tend to flex, losing its perpendicularity to the work plane and thus generating cuts out of square.

with hot wire it is possible to cut

- expanded plastics: polyurethane foam, polystyrene, expanded polystyrene.

it is not possible to cut

- laminated expanded plastic sheets, such as Poliplat and Kapa

- slabs of expanded polyurethane

- rigid plastics

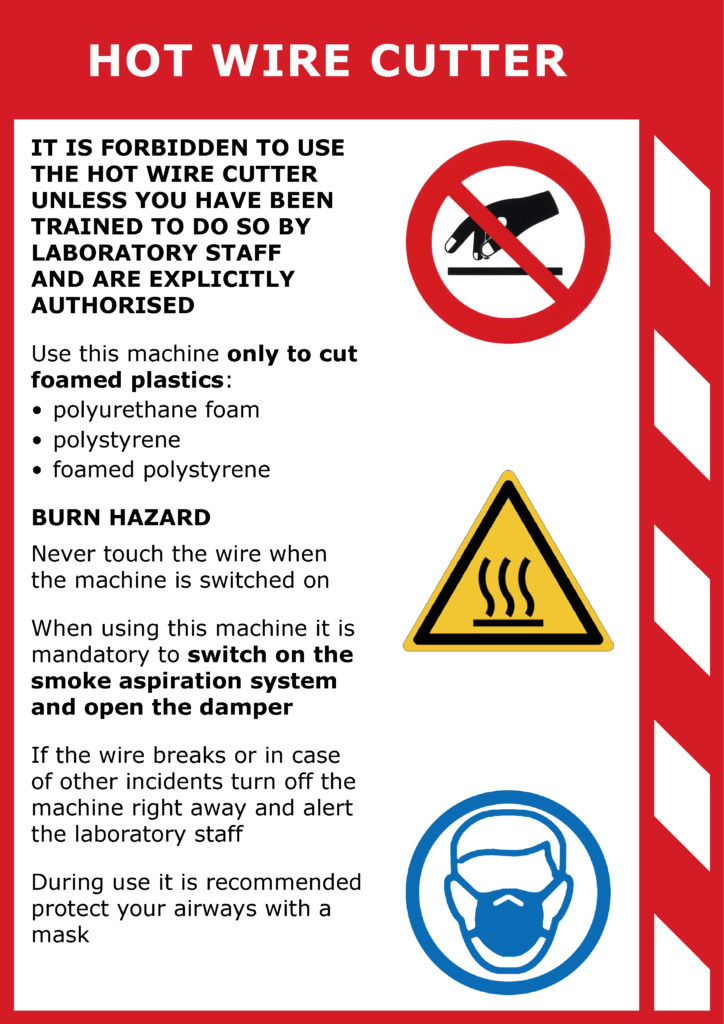

prohibitions and regulations